Projects on tomorrow's elastomer solutions

With 5% of our turnover invested in research each year, ITC Elastomères is an industrial player committed to understanding the behavior of elastomers and developing new materials and processes. Our goal is to always respond better to the current and future needs of our customers with adapted and smart solutions.

From material to application

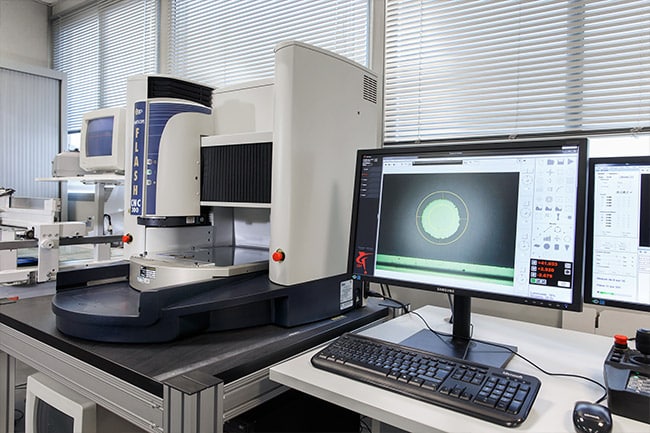

Equipped with numerous simulation, control and testing tools, the ITC laboratory participates in and initiates numerous collaborative or private research projects in order to validate the physicochemical characteristics of rubber compounds and their behavior in the working environment.

| Materials tests | Density, vulcanization characteristics, Shore/DIDC hardness, tensile stress-strain characteristics, tear strength, low temperature testing, DRC measurement, resistance to accelerated aging, resistance to liquids |

| Dimensional control | 2D and 3D contactless control means and optical profile projector |

| Test benches | Airtightness test, watertightness test, tear-off test, mountability test, ad hoc functional tests |

Our current research projects

FLAMS (FLuorosilicons Ageing, Mechanics & Synthesis)

Long-term aging of fluorosilicones (FVMQ)

FLAMS (FLuorosilicons Aging, Mechanics & Synthesis) focuses on predicting the lifespan of fluorosilicones via a kinetic approach and identifying end-of-life criteria. The project aims to develop fluorosilicones with better short-term (processability, chemical resistance, mechanical properties) and long-term (aging) properties.

FabAddSilicone – Silicone additive manufacturing

Study of the additive manufacturing of silicone parts

The objective of this project is to manufacture technical parts in right material silicone elastomer and to avoid tooling costs for small series parts.

Smart Rubber

Elastomer intelligence applied to industrial maintenance

ITC is involved in a collaborative predictive maintenance project in the aeronautical field.