A high quality standard

Since its creation, ITC has been committed to a Total Quality approach in order to guarantee the highest level of compliance between the services provided and the requirements of its customers.

Choice of materials in compliance with regulations, traceability of batches throughout the production process, production processes checked regularly, we ensure seamless production quality meeting the requirements of our customers.

The primary objective of ITC ELASTOMERES is therefore to offer a complete control from developing to converting elastomers while associating the management of people and their skills.

Our commitments

- Customer satisfaction based on the best customer service

- Innovation and continuous development in every department of the company

- Optimizing added value creation

Our certifications

In order to provide the best quality to our customers and meet the regulatory requirements of our markets, we rely on the ISO 9001 quality management system and EN9100 certification, tailored to aerospace requirements.

A continuous improvement process

ITC has implemented a quality management system based on Lean principles of performance research in order to improve our production quality and deadlines for our customers.

We design the layout of workstations with our employees as part of a 5S plan. This program allows us to improve the ergonomics of workstations, facilitate production flows and promote quality of life at work.

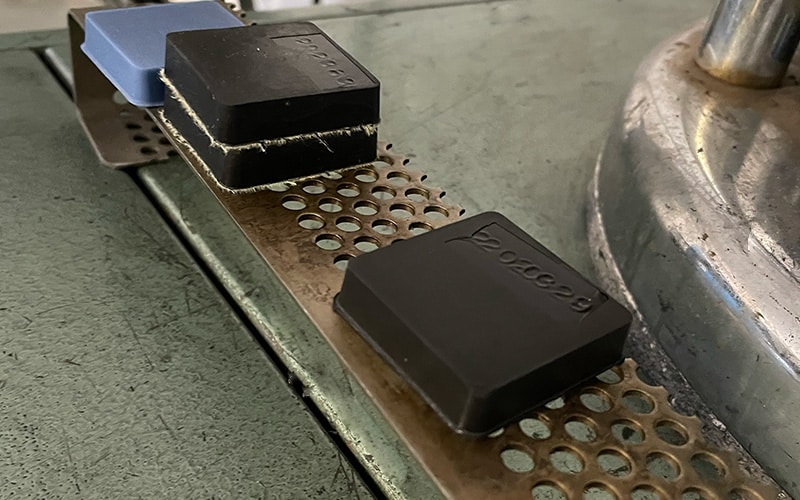

All batches used for our production are preserved to allow perfect traceability.

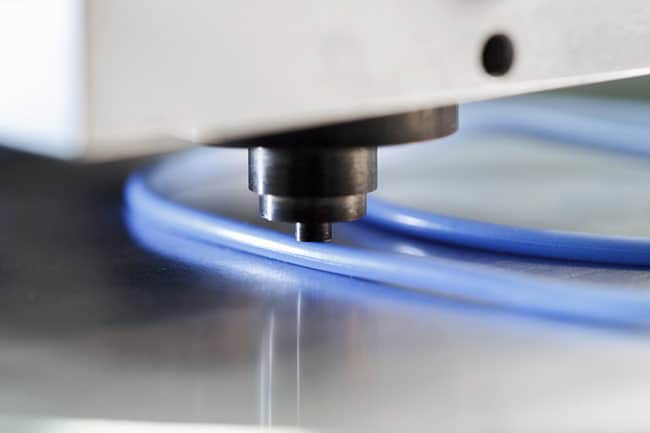

Numerous binocular visual, dimensional or functional checks are carried out on our products.

Lean work meeting in a workshop