What is vacuum casting?

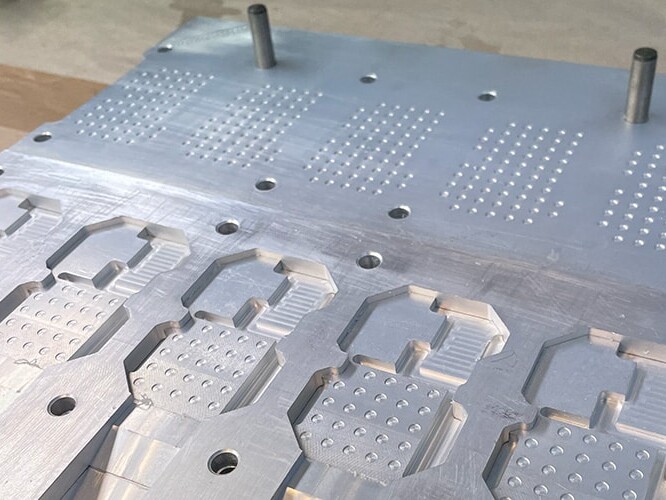

Vacuum casting is a technique used for the production of small series of functional parts. Using various liquid silicone, PU or other resin materials and tooling resin or aluminum molds, vacuum casting is known for its rapid production of high-quality prototypes or finished products.

Silicone molding results in high quality parts comparable to compression, transfer or injection molded components. This makes vacuum cast models particularly suitable for fit and function testing, or final part runs in limited quantities. Vacuum casting also allows a variety of degrees of finishing, and we can provide you with the finish you need for your parts.

This technology is therefore ideal for pre-series or low productions which will have the same appearance and mechanical properties similar to those of the final product.

The quality of finish and the precision of the molding of parts made by vacuum casting make it a technology appreciated in the most demanding fields from aeronautics to the luxury industry.

Vacuum casting at ITC

Our liquid silicone/PU workshop is able to produce from a simple concept to prototypes for testing or pre-series for demanding environments such as for aerospace applications.

The impression sizes of our machine allow us to produce parts from a few grams to several kilos.

The production steps of vacuum casting

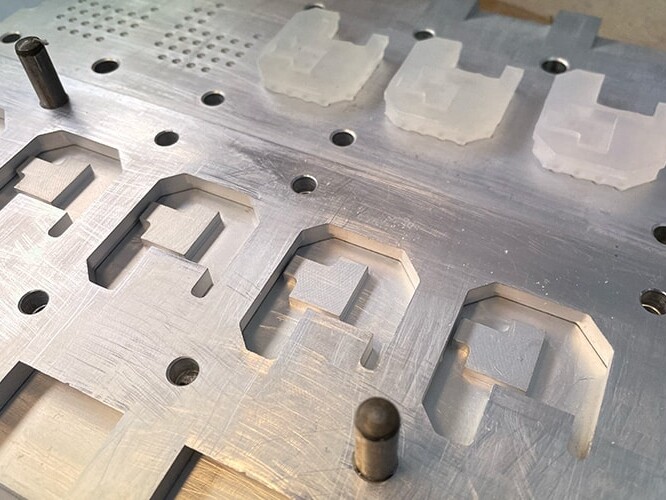

Allowing the creation of parts that can be used for a trial, a pre-series or a concept test, the 3D prototypes resulting from this technology come from a silicone mold created from a master model designed in advance or produced directly in printing 3D from the customer’s part file.

The silicone mold created using the master model will then be filled with polyurethane resin, silicone or specific resin, using a specific vacuum casting machine.

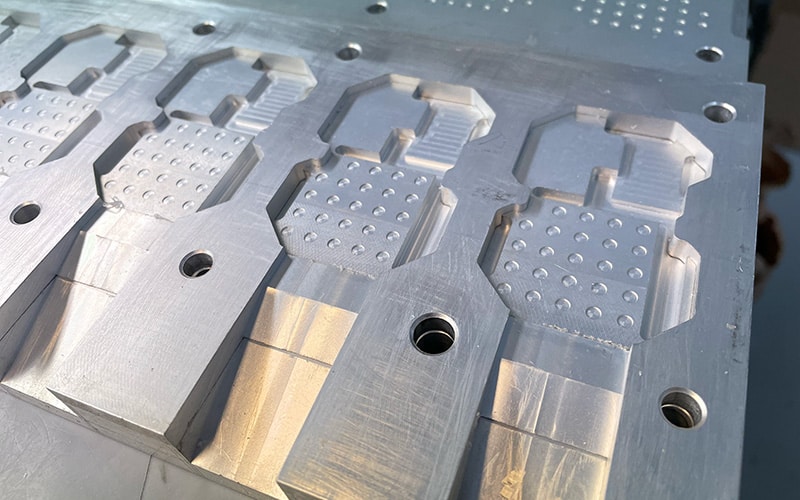

The lifespan of the mold varies depending on the geometry of your parts and the polymer used.

The dimensions of our vacuum chamber are L 200 X l 200 X h 200mm and allow us to produce parts with a volume of up to 1500 cm3 in a very short time.

We can make up to 100 copies per mold depending on the material, the complexity and thickness of the mold walls as well as the grade of polymer used.