Tests and controls at ITC

In order to guarantee the quality of our products, we carry out various tests and checks to guarantee the conformity of the products manufactured to your specifications and to the standards of our sector.

From raw material supply to finished molded product, we control each step scrupulously. We keep sample batches of all our formulas and keep the results of our tests to allow you to have excellent traceability on your products.

Material control

Our laboratory is equipped with machines and control equipment allowing the validation of rubber mixtures and products during manufacture.

We ensure full traceability of raw materials, mixtures, inserts and parts, as well as production parameters.

| Type of tests | Standards |

| Determination of vulcanization characteristics using the oscillating disk rheometer | NF ISO 3417 |

| Determination of penetration hardness (SHORE hardness) | NF ISO 7619-1 |

| Determination of hardness DIDC | NF ISO 48 |

| Détermination des caractéristiques de contrainte-déformation en traction | NF ISO 37 |

| Determination of tear resistance | NF ISO 34-1 |

| Determination of low temperature characteristics, temperature-shrinkage method (TR test) | NF ISO 2921 |

| Determination of fragility at low temperatures | NF ISO 812 |

| Determination of density | NF ISO 2781 |

| Resistance to accelerated aging and heat test | NF ISO 188 |

| Determination of compression set | NF ISO 815-1 |

| Determination of the adhesion of a rubber to a rigid substrate | NF ISO 813-2010 |

| Determination of the action of liquids | NF ISO 1817 |

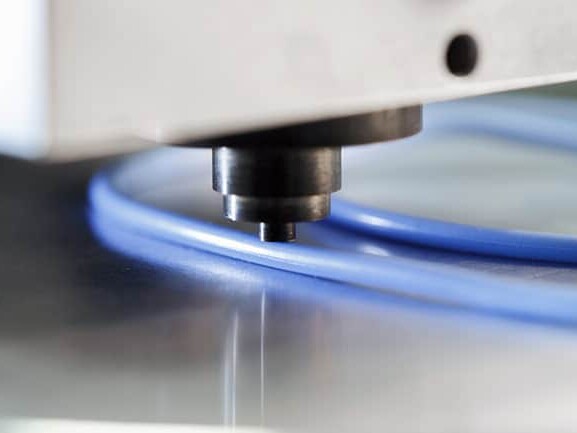

Dimensional control

Our laboratory is equipped with 2D, 3D and optical profile projector contactless control means.

We can thus respond to controls of tolerances usually required in our business:

NF ISO 3302-1 (shaped parts)

NF ISO 3601-1 (O-rings)

Visual control

From sampling inspection to 100% unit inspection on certain productions, we adapt the visual inspection according to your specifications and your constraints.

We have established a workshop specializing in Class S O-rings in accordance with ISO 3601-3 for applications requiring a high level of quality and/or dimensional accuracy.

More in-depth visual inspection, more precise dimensional tolerances, this workshop is organized to meet the needs of the aeronautical/space/defense and motorsport markets.

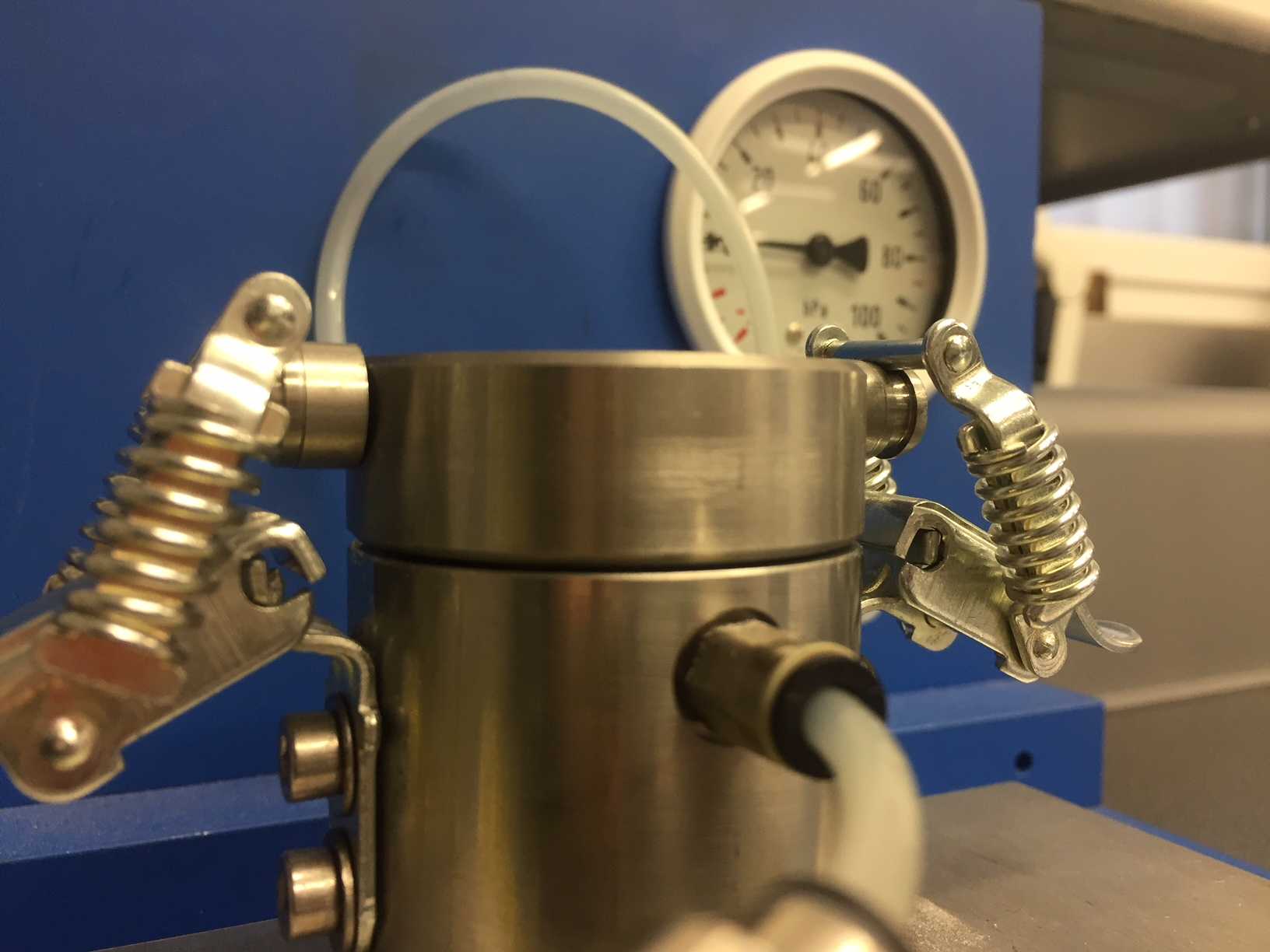

Bench tests

We implement different tests such as:

- tightness test to air, water, different solvents or chemicals

- peel test

- temperature resistance test

- mountability test

Beyond standard tests, do not hesitate to consult our team to set up specific functional tests for your application. We are here to help you ensure the performance of your equipment.