What is mixing?

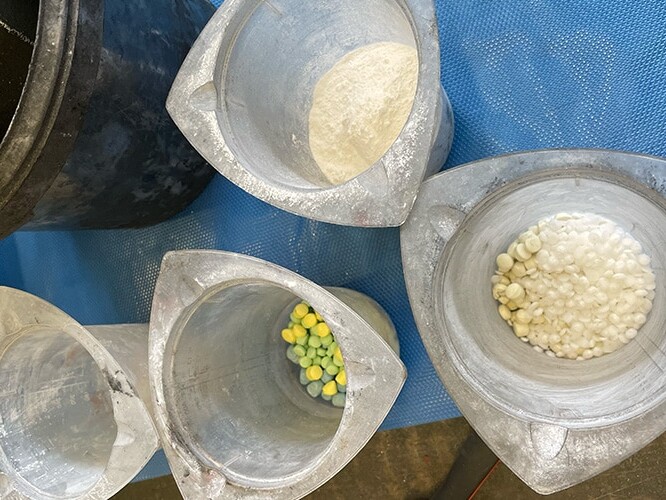

Before being transformed into parts of various sizes or dimensions, rubbers must be formulated, which requires the manufacture of a mixture. Mixing is a key operation in the manufacturing process of a rubber part. Indeed, the quality of the molded part is conditional on the quality of the mixture. “Mixing” consists of strongly kneading the rubber to incorporate and disperse, in a determined order and under well-defined shear and temperature conditions, the fifteen or so ingredients of the “formula” previously established according to the application. .

This operation is carried out either using an external mixer with cylinders or using an internal mixer with secant or tangent rotors. The conduct of this operation is increasingly automated for internal mixers through appropriate control of incorporation times, temperature and absorbed power.

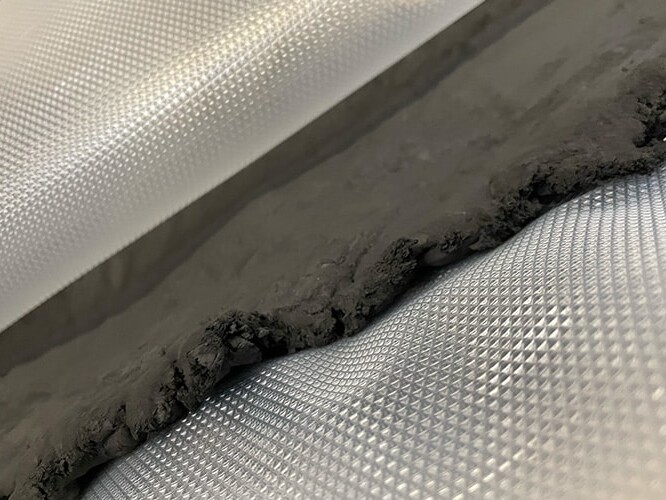

At the end of mixing, the mixture is put into sheets or strips, cooled, checked and stored before being shaped.

Mixing at ITC

Our mixture manufacturing workshop allows us to produce standard or specific mixtures with great responsiveness for our various molding workshops. Adjuvants, additives, plasticizers, vulcanization agents or accelerators are added to perfectly match the details of your specifications. We test each batch to ensure the quality and reproducibility of the formulations.

We use substances of consistent quality and products with a long-term supply. All our suppliers meet specifications strictly drawn up by ITC.

The quality of our formulations is the result of our more than 50 years of experience in elastomeric applications. The formulations produced by ITC strictly meet your specifications. But to ensure this, our laboratory carries out manufacturing controls on all batches of mixtures: rheological controls, physico-chemical controls or specific controls depending on your requests.