What is LSR injection?

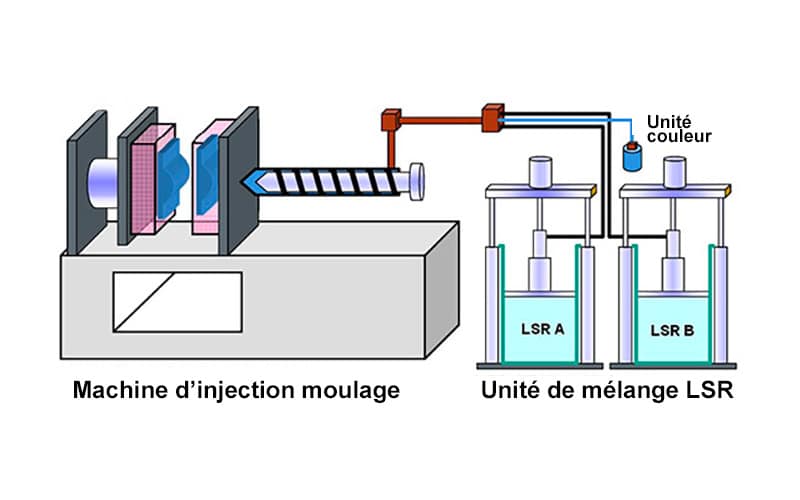

LSR (Liquid Silicone Rubber) injection consists of mixing then injecting the silicone under pressure into the mold cavities. This is an innovative technology providing significant yields for high quality parts. LSR technology has many advantages:

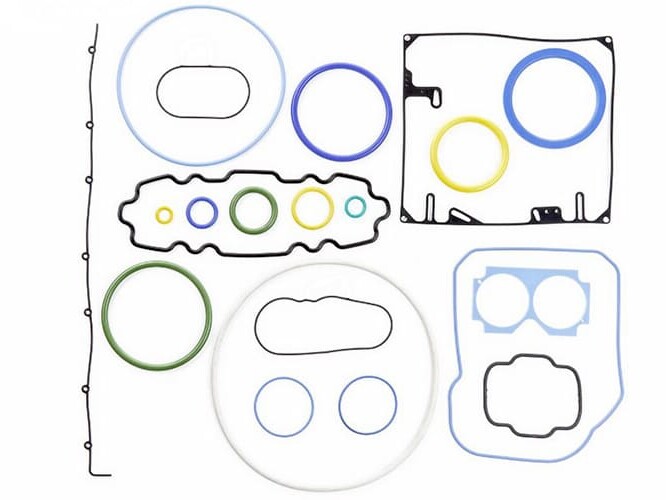

- Unrivaled part quality allowing the production of parts with complex geometry, with fine thicknesses and within tight tolerances

- A fast process with automated and short cycle times, especially compared to HCR (Heat Cured Rubber) technology

- Excellent repeatability thanks to an automatically controlled process and batch injection of stable ready-to-use material

- Waste-free technology: no loss of material during transformation by direct injection and no post-molding deburring

LSR injection at ITC

Our press is a medical version under ISO7 laminar flow which allows us to produce high-precision parts for the most demanding industries. LSR (liquid silicone rubber) due to its chemical composition is inert. It is biocompatible, hypoallergenic and non-allergenic, which makes it perfectly suited to applications in the medical industry or food contact in general. This material also makes it possible to offer a reliable solution to the problems of migration or possible interactions with the active ingredients used. Available from 20,000 pieces/year, do not hesitate to contact us for all your complex elastomer part projects

LSR injection makes it possible to achieve precise injection dosages and perfect control of all stages of the process without interference from foreign bodies coming from handling for example. The pumps take the material necessary to manufacture the parts without any human contact and inject it into a heated mold. Some parts can then undergo a post-curing step at high temperature in order to finalize the vulcanization process. This final step ensures good mechanical properties, and eliminates volatile organic substances prohibited in applications subject to specific regulatory requirements.

Many applications with a fine, homogeneous and aesthetic finish are possible with LSR injection. Perfectly suited to use at over 200°C continuously, it allows for numerous applications as a thermal barrier in cauterization instruments or for medical devices that must be sterilized by heat. It also allows simple sealing of lids, applications in the food sector or in personal hygiene. Depending on the characteristics and specific functionality sought for your application, we select the most appropriate LSR (liquid silicone rubber) in terms of range and grade.