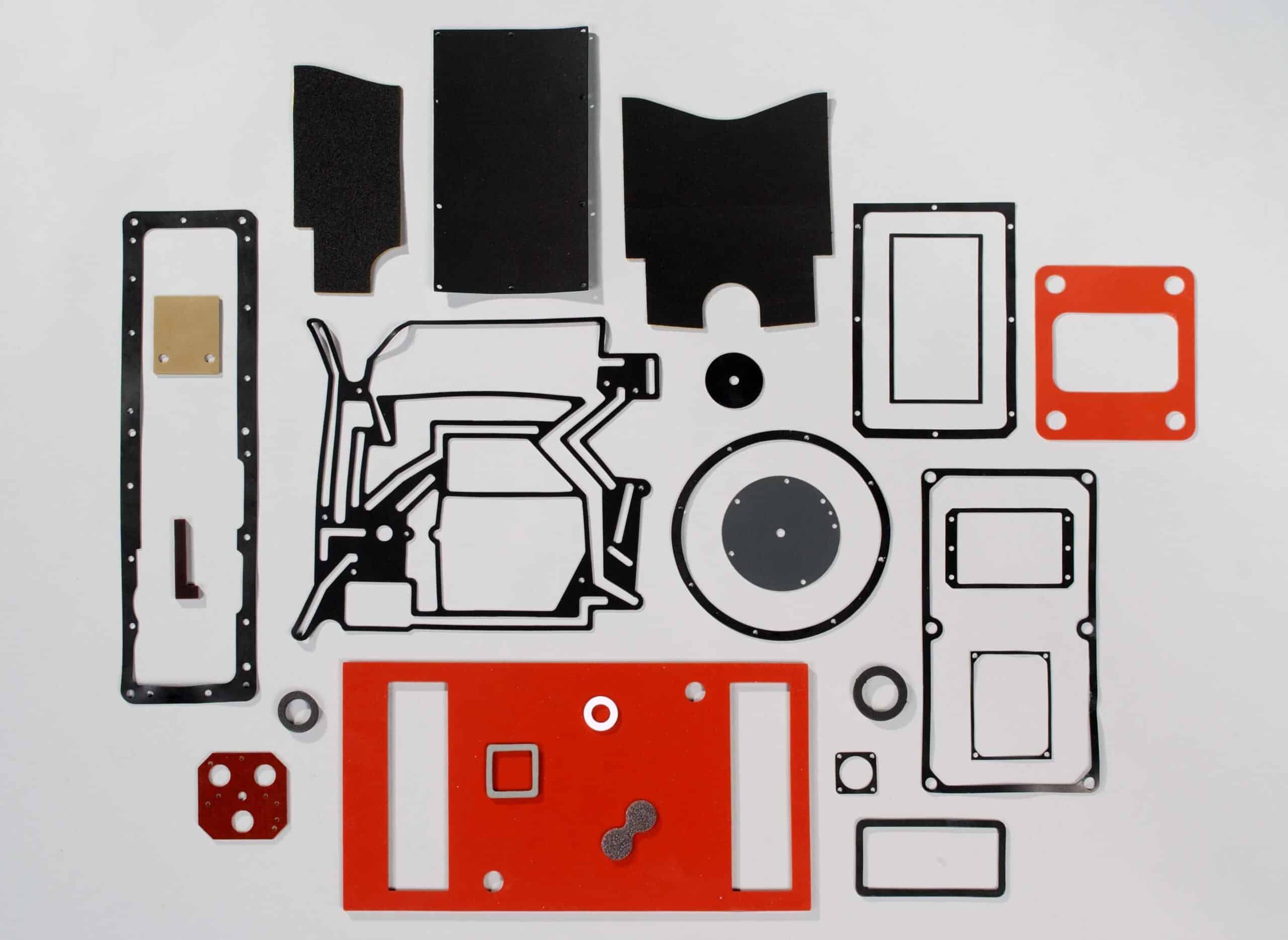

What is die-cutting?

Die cutting is a very versatile manufacturing process that typically involves a press and a pre-cut shape (called a die or die), to cut, shear or deform the material into the desired shape. Several types of die-cutting exist on the market depending on the materials to be cut. For elastomers, we mainly use flat cuts or water jet cuts from calendered plates in order to obtain precise cuts. Waterjet cutting is an excellent process for precisely cutting quantities of thicker or thinner materials using high pressure water.

Die-cutting at ITC

At ITC, we offer a range of cutting processes to meet the needs of many applications. Our facilities include various cutting equipment for a full range of manufacturing possibilities. We offer various cutting solutions from plates made in our factory:

- Cutting net tool on substrate

- Cutting with forged tool

- Waterjet cutting

Each method offers unique advantages for particular product designs and materials.

We use a variety of die designs and equipment to provide the ideal die cutting technique for your specifications. Fillet-to-Support Dies: This cutting method uses pre-formed steel dies bent into the shape of the desired component. The dies are pressed into the elastomeric plate, which sits on a die board, cutting the material into the shape of the die. Forged Dies: Custom forged dies are less flexible than steel thread dies. They use a similar press mechanism and provide more precise cutting results due to the increased structural strength of the die. Although these dies are made from the same steel material, the tooling process required to create the forged die makes them a more expensive option.

Die cutting can be used in any industry requiring the manufacturing of a high volume of products with uniform shapes, precisely defined dimensions, or complex design elements. Allowing rapid manufacturing and high precision, die cutting is the method of choice for various industrial applications. Thus, cutting has become the industrial standard for the production of gaskets, washers, medical components, vehicle parts, etc.