Elastomer science applied to your sector

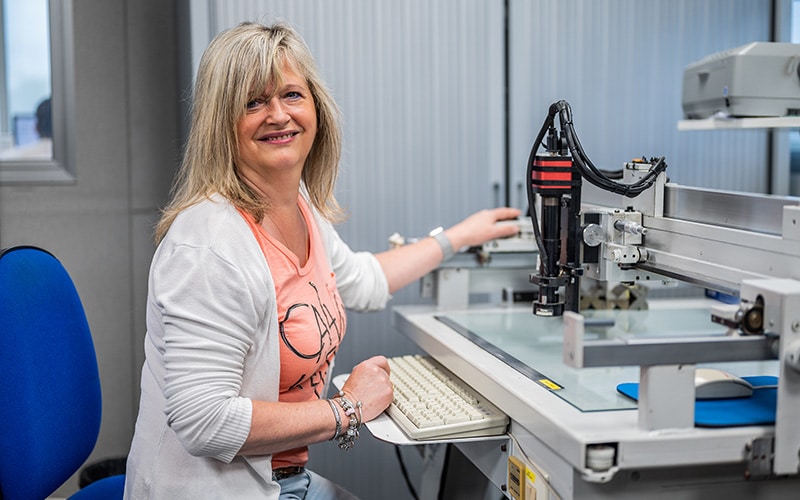

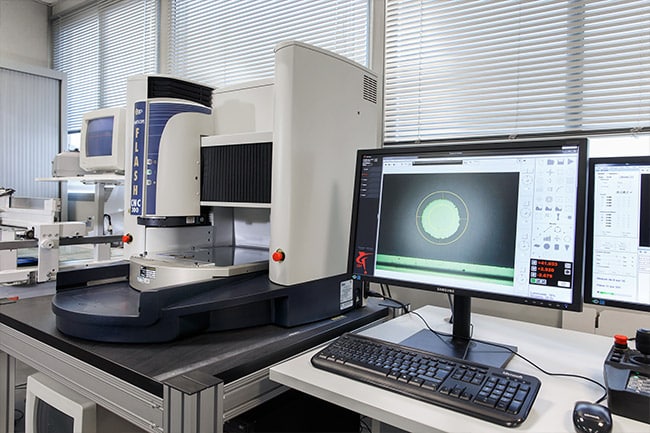

We have our own design office integrating the design of parts and tools, simulation techniques and a control laboratory.

Involved as early as possible in industrial projects, we are able to recommend, design and manufacture innovative sealing, fluid transfer or damping solutions combining multiple technical requirements whatever your sector of activity. .

Thanks to our development and control laboratory, we can:

- develop specific elastomer formulations,

- characterize their physicochemical properties,

- optimize molding processes

5% of our turnover is dedicated to Research and Development

Our prototype department

We offer various solutions for creating functional demonstrators and prototypes in the material adapted to your project:

Print reported in carcass

- Economical solution

- Molding in the same material as the series

- Short lead times

Cut parts

- By water jet or cutting tool

- Production of plates in the same material as that of the series

- Economical solution

3D SLS (Selective laser Sintering) printing

- Rapid creation of 3D printing tools

- Molding of parts from silicone or PU resin

- Economical solution compared to machining a mold

Co-design - ITC's expertise at your service

Because you know the needs of your markets well, we offer technical support to accelerate the development of solutions adapted to your products and within your budget.

Thus, from formulation to production of parts with or without inserts, we ensure complete management of your sealing, damping, fluid transfer or smart rubber projects.

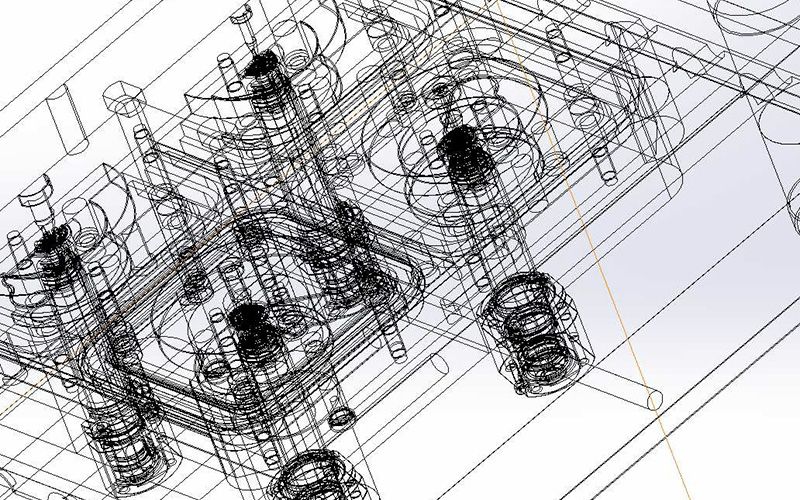

We have additive manufacturing and 3D design tools to create not only prototypes and interface solutions but also the tools adapted to our different transformation technologies:

- Compression

- Transfert

- Injection

- Cutting

- LSR (Liquid Silicon Rubber)

We constantly adapt and optimize our solutions and our industrial tools to support changes in demand from our customers and the market.

Our experience in co-development, our formulation science and our mastery of various elastomer transformation processes make the ITC team a preferred contact for innovative elastomer solutions at controlled costs.

Some of our skills

Customized formulations

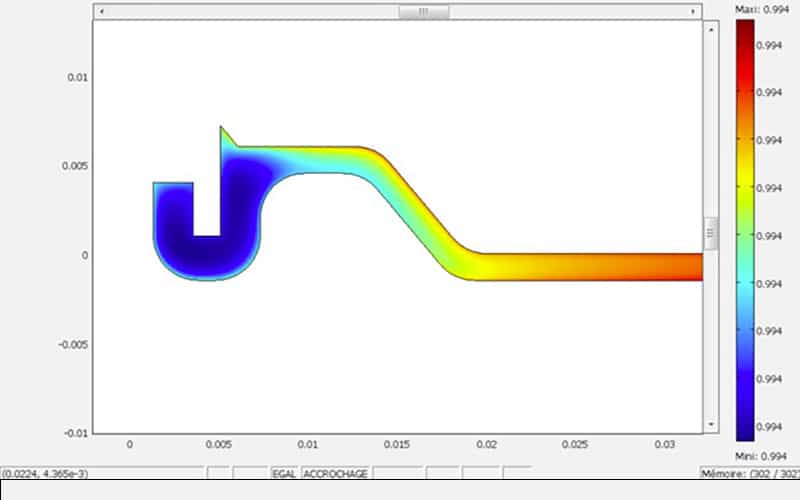

Simulation of flow in imprints

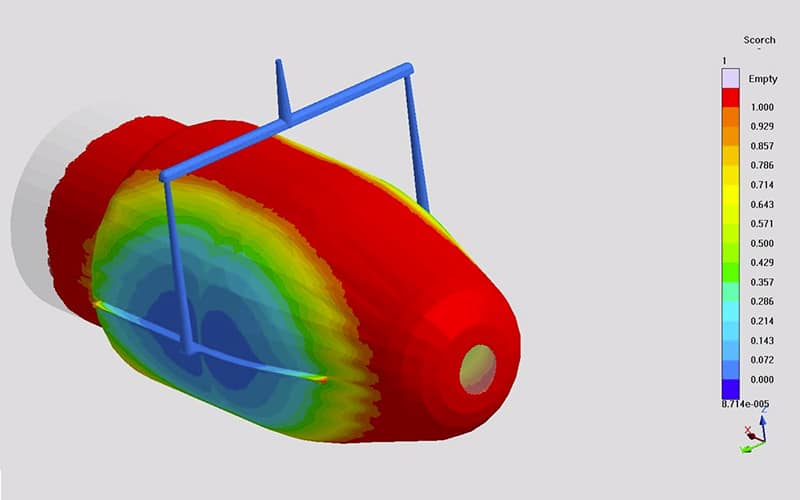

Vulcanization simulation

3D tool design