Waterproof seals for fixed parts

Tightness is defined according to the behavior of mechanical parts linked by a seal. If the two parts between which a leak is likely to occur are fixed relative to each other, then it is static sealing. Flat or O-ring seals are the most common sealing device and their effectiveness is no longer in doubt. You still need to select the elastomer mixture that will withstand the constraints of your application.

Under static sealing application conditions, parameters such as pressure and temperature variations can cause relative movements between the seal and the surfaces with which it is in contact. Consequently, wear problems and superficial lesions may occur, risking compromising the seal.

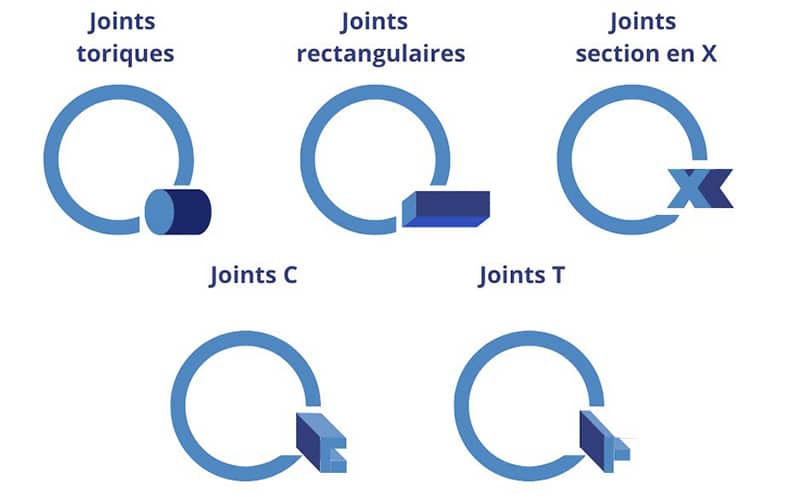

This is why, at ITC Elastomers, we co-develop and design the different shapes of seals which will adapt perfectly to your housing plans and dimensions and will guarantee you a good sealing level.

Applications

Whether in the automobile and motorsport industries or in the petrochemical or food industry, you need high-performance sealing systems for your applications.

Resistance to water, air, water vapor, gases, oils, solvents but also constraints linked to more solid elements such as dust and sand must be taken into account for good sealing.

Likewise, the stresses and temperature variations to which your joints will be exposed are also an essential component in the choice of the elastomeric material to use.