Certified raw materials

Since we started operating, we have sought the best technical solutions for our elastomer formulations, always favoring the most environmentally friendly raw materials.

All the raw materials we use are REACH (Registration, Evaluation, Authorization and restriction of CHemicals) and ROHS (Restriction of Hazardous Substances in electrical and electronic equipment) certified.

Our natural rubber comes from sustainably managed rubber forests and is FSC (Forest Stewardship Council) certified.

Furthermore, we participated in a collaborative project aimed at working on the substitution of raw materials from petroleum with biosourced products:

- Polymer

- Black from the pyrolysis of used tires

- Vegetable plasticizer

- Powder recycling

Over 250 formulations compliant with Reach and RoHS directives

Waste reduction and recycling

At ITC, we valorize raw materials as much as possible in order to reduce our waste of vulcanized materials.

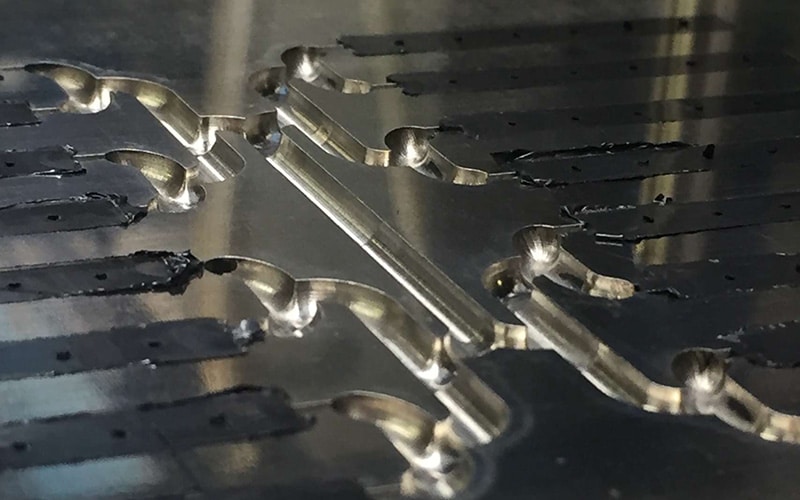

Plate cuts are optimized and injection mold feed channels are calculated to minimize sprues. In addition, we are launching a program to recycle materials by devulcanization.

We mix precisely and without any waste in order not only to guarantee the quality of our formulas but also not to pollute the environment.

The natural rubber used by ITC comes from sustainably managed forests.

Carbon black from the pyrolysis of used tires

Optimization of cuts and reduction of raw material waste

Optimization of supply channel sizing