Test co-development made in ITC!

Are you looking for a sealing solution for application in a constrained environment?

The ITC team supports you in the co-design of your part and the choice of elastomer according to your specifications.

- Validation of required functionalities in resistance to compression, temperature or aggressive fluids

- Creation of prototypes

- Design of parts and the corresponding mold

Starting from a blank sheet of paper to define your sealing solution is our job!

ITC, expert of elastomer overmolding

Do you have a plastic part to which you would like to add a seal or an elastomer element?

At ITC, we specialize in overmolding and adhesion in order to produce interdependent multi-material parts.

We use all types of materials such as in this valve which combines a carbon fiber reinforced polyamide with a silicone seal (circled in red).

Do you have a flap, a valve, a valve to make in multi-materials? Check out ITC!

More information on our adhesion/overmolding skills.

Official handover of the keys to the Toury site!

It is with immense pride and after many months of work that Christophe Beauvais received the keys to our new Toury site today. A symbolic moment which marks the start of a new year marked by growth and innovation.

This brand new site, designed with an eco-responsible approach, reflects our commitment to the future: combining performance, sustainability and well-being at work.

A big thank you to all the teams and partners who made this project possible.

Happy New Year 2025!

The entire ITC Elastomères team sends its warmest wishes to all our clients and partners for this new year. May 2025 be filled with success, innovation, and prosperity for you, your teams, and your projects!

For ITC Elastomères, 2025 will mark a major milestone as we move to our new site in Toury.

A state-of-the-art facility designed to meet the highest quality standards and prepare us for the challenges and opportunities of tomorrow.

We look forward to sharing this new chapter with you and continuing to build a future full of success and innovation together.

Wishing you all a wonderful 2025!

Happy Holiday Seasons from the whole team!

As the holiday season begins, we want to take a moment to thank all our customers and partners for their trust and collaboration throughout the year.

We wish you and your loved ones a season filled with joy, warmth, and relaxation.

Happy Holidays from all of us at ITC Elastomères!

Test your parts in the application conditions

Would you like to test your parts in the environment where they will be used?

We are here to help ensure the performance of your equipment.

We test the sealing of your parts with various fluids (kerosene, solvents, water, etc.).

Beyond standard testing, feel free to consult our team to set up custom functional tests tailored to your application.

Find out more about our testing services.

High-Performance Elastomer Solutions for Watchmaking

At ITC Elastomères, we leverage our expertise in high-performance elastomer engineering to create solutions that combine:

- Technical Reliability: Built to withstand mechanical and environmental challenges.

- Aesthetic Excellence: Impeccable materials and finishes to uphold the elegance of luxury watches.

- Innovation: Integrating cutting-edge technologies while preserving the authenticity of traditional watchmaking expertise.

Whether it’s shaped or overmolded parts, sealing joints, or elastronic components, want to learn more? Contact us!

Renewal of our quality certificates

We are delighted to announce the renewal of our ISO 9001 and ISO 9100 quality certificates for a period of 3 years!

Ce renouvellement témoigne de notre engagement continu à offrir des produits et services de haute qualité à nos clients, en particulier pour le secteur aéronautique. ✈️ Un grand merci à nos équipes pour leur travail et à nos partenaires pour leur confiance.

Découvrez nos nouveaux certificats ici.

ITC Elastomers is expanding its portfolio of elastomer formulations

We are delighted to announce the addition of new elastomer formulations to our range, specifically designed to meet:

- the needs of aeronautics and hydrogen

- the latest European regulations

- certain particularly demanding applications (pressure, temperature)

- and sometimes all three at once!

To find out more about our new offers and find the solution that meets your needs, contact us now!

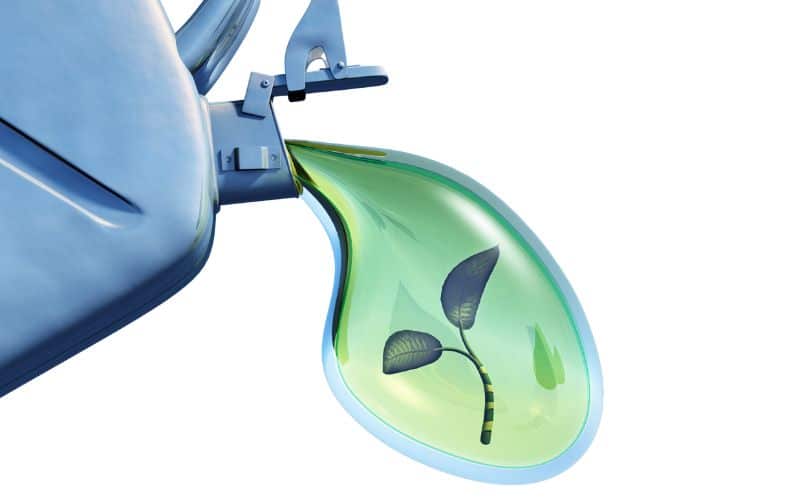

ITC commits to the challenges of sustainable fuels

The chemical composition of sustainable fuels presents new challenges for manufacturers, including increased constraints on seals and elastomer parts.

At ITC Elastomers, we support our customers in the energy transition by developing high-performance elastomers resistant to the corrosive effects of ecological fuels.

Our formulations guarantee better durability and performance, thus meeting the strict requirements of the industry and the need to preserve our planet.

Let’s continue to innovate for sustainable mobility!